Wheelchair Mounted Umbrella

OBJECTIVE

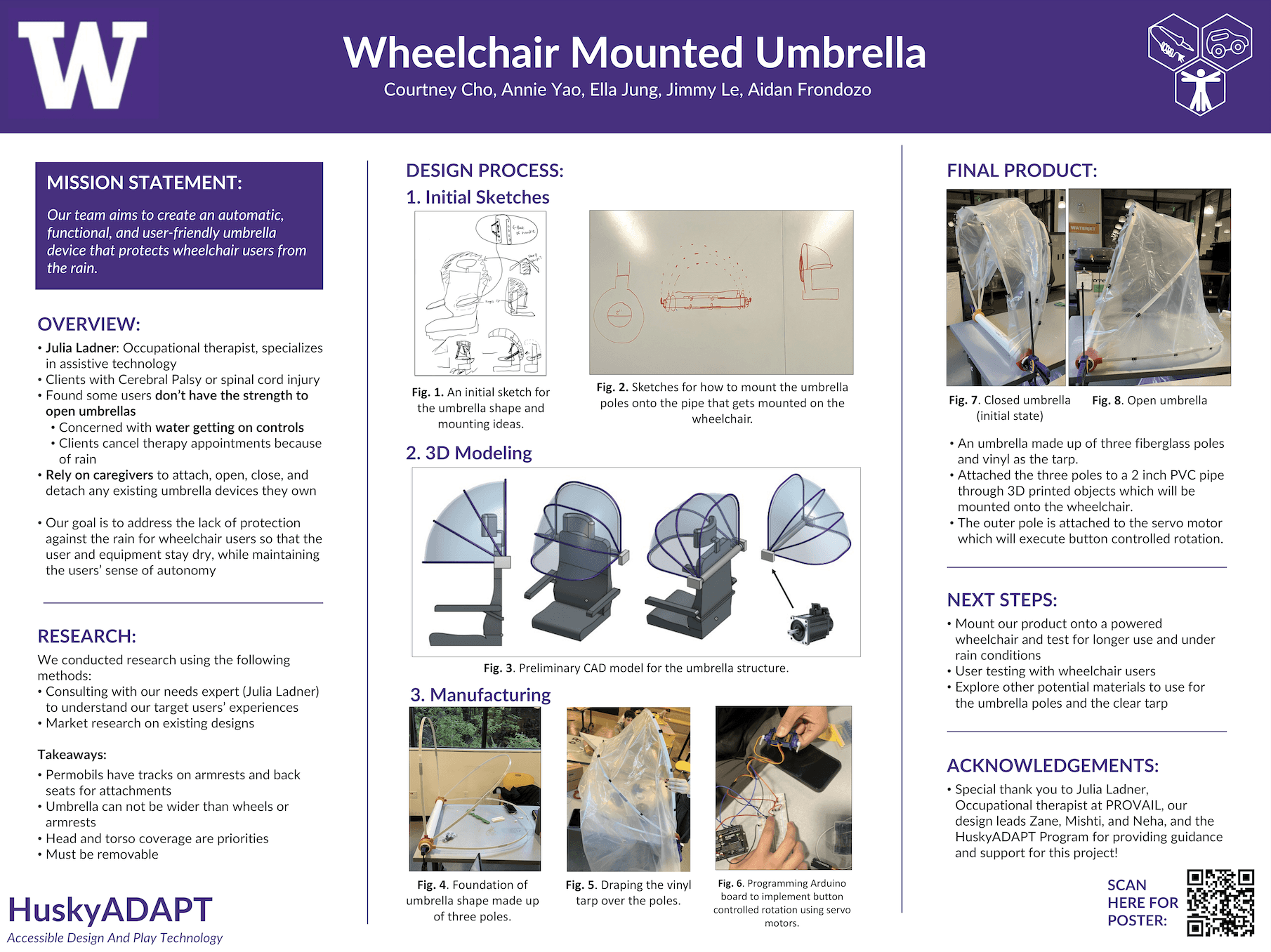

To create an automatic, functional, and user-friendly umbrella device that protects wheelchair users from the rain.

OVERVIEW

ORGANIZATION: HuskyADAPT at UW

ROLE: Co-Lead Designer

TEAM: Courtney C. (Co-Lead Designer), Ella J. (Designer), Jimmy L. (Engineer), Aidan F. (Engineer)

TIMELINE: 2023-2024 Academic Year

KEY AREAS: User Research, Accessibility, Market Research, Design & Prototyping, Assistive Technology, Testing

PROBLEM CONTEXT

Julia Ladner, an occupational therapist at PROVAIL who specializes in assistive technology, came to HuskyADAPT with this new project idea. She works with clients that have cerebral palsy or spinal cord injuries and use powered wheelchairs. These problems spurred her intent:

Some users don't have the strength to open umbrellas

Concerns with water getting on the controls

Clients cancel therapy appointments if there's rain… and there's a lot of rain in Seattle

Rely on caregivers to attach, open, close, and detach any existing umbrella devices on the market

Our goal is to address the lack of protection against the rain for wheelchair users so that the user and equipment stay dry, while maintaining the users’ sense of autonomy.

RESEARCH

We conducted research using the following methods:

Interviewing Julia and a wheelchair user to understand our target users’ experiences

Market research on existing designs

TAKEAWAYS:

Almost all existing wheelchair umbrellas on the market are made for manual wheelchairs. Any that are for powered wheelchairs are unaffordable or hard to find.

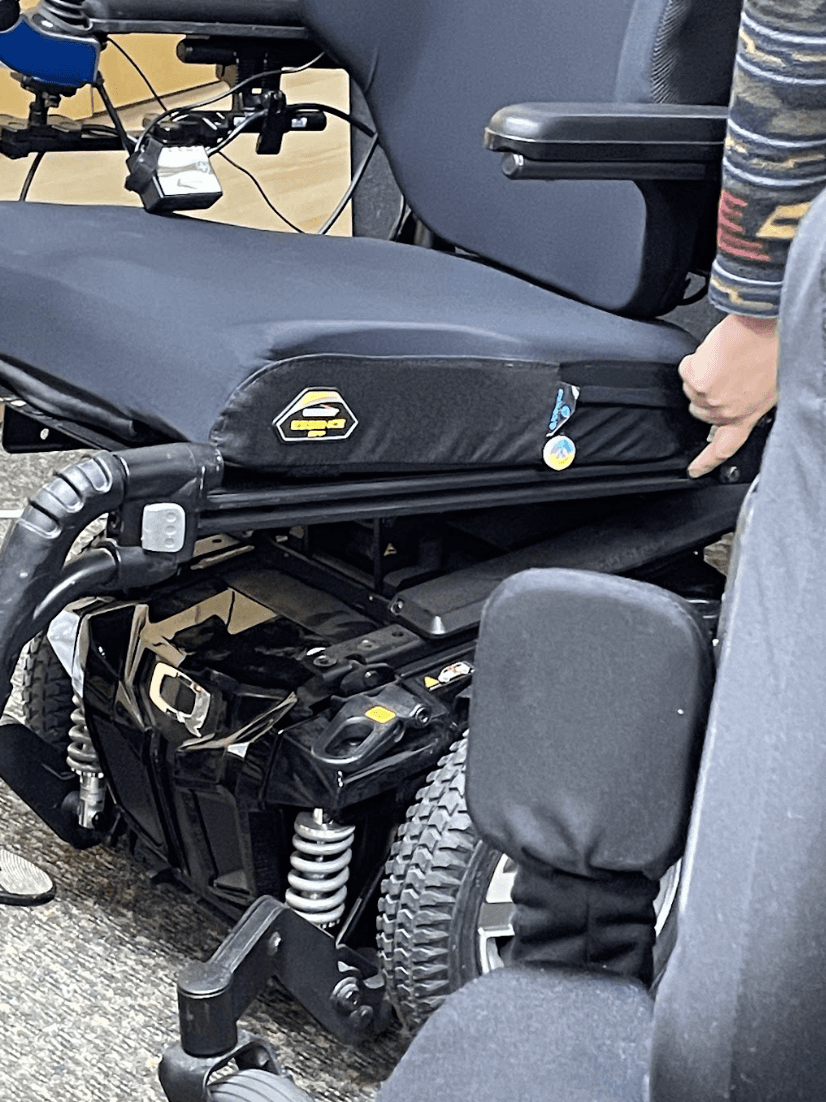

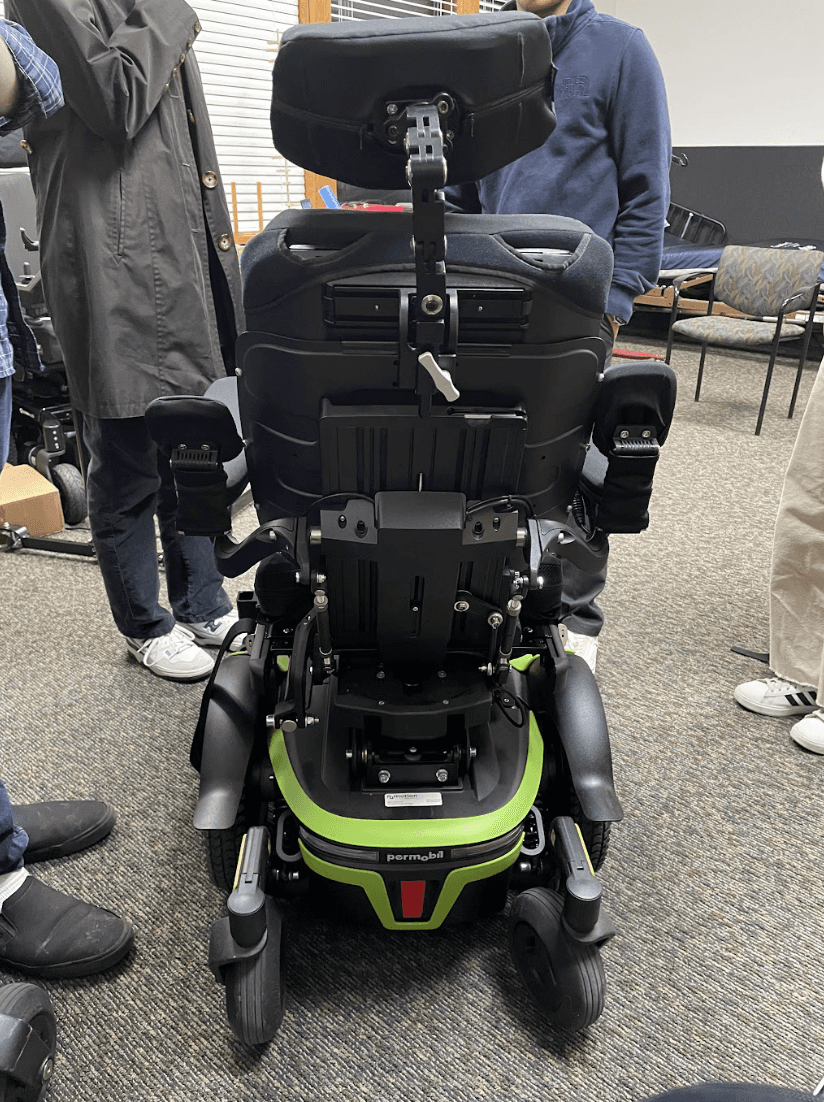

Permobils have tracks on armrests and backseats for attachments

Umbrella can not be wider than wheels or armrests

Head and torso coverage are priorities

Umbrella must be removable

Connect to disability-adapted switch for easy use to eliminate the need for someone else open the umbrella for them

INITIAL SKETCHES

Next, our top two questions were about the umbrella's shape and how it would mount to the chair.

SHAPE

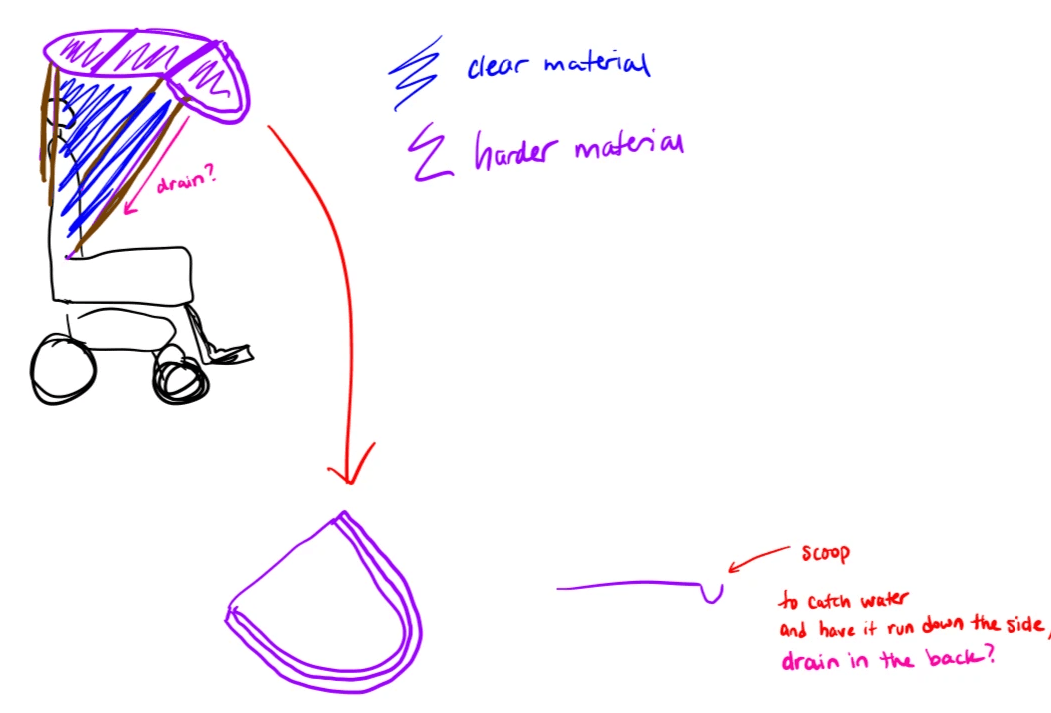

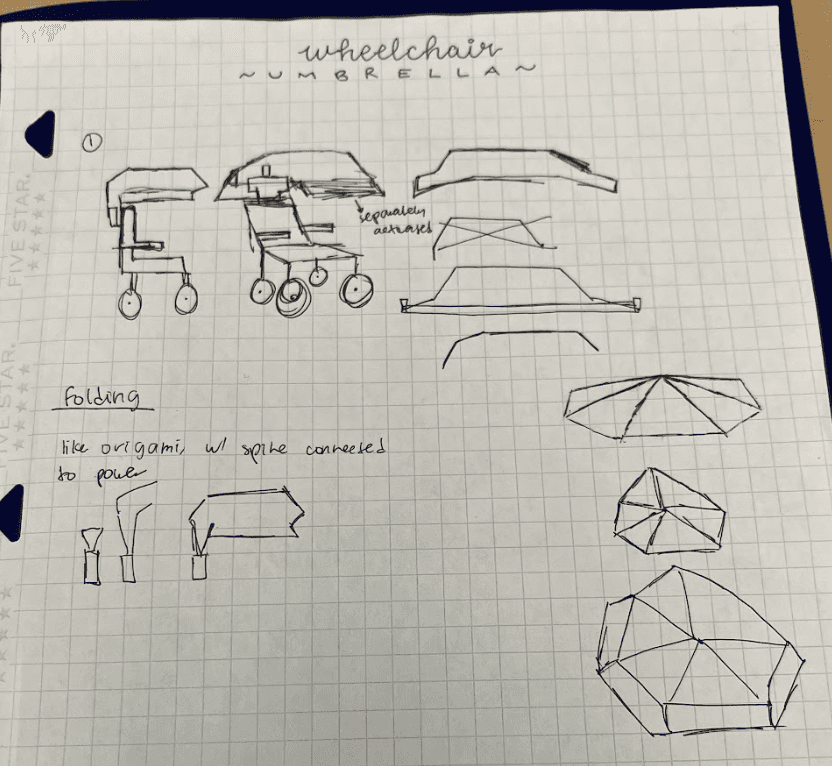

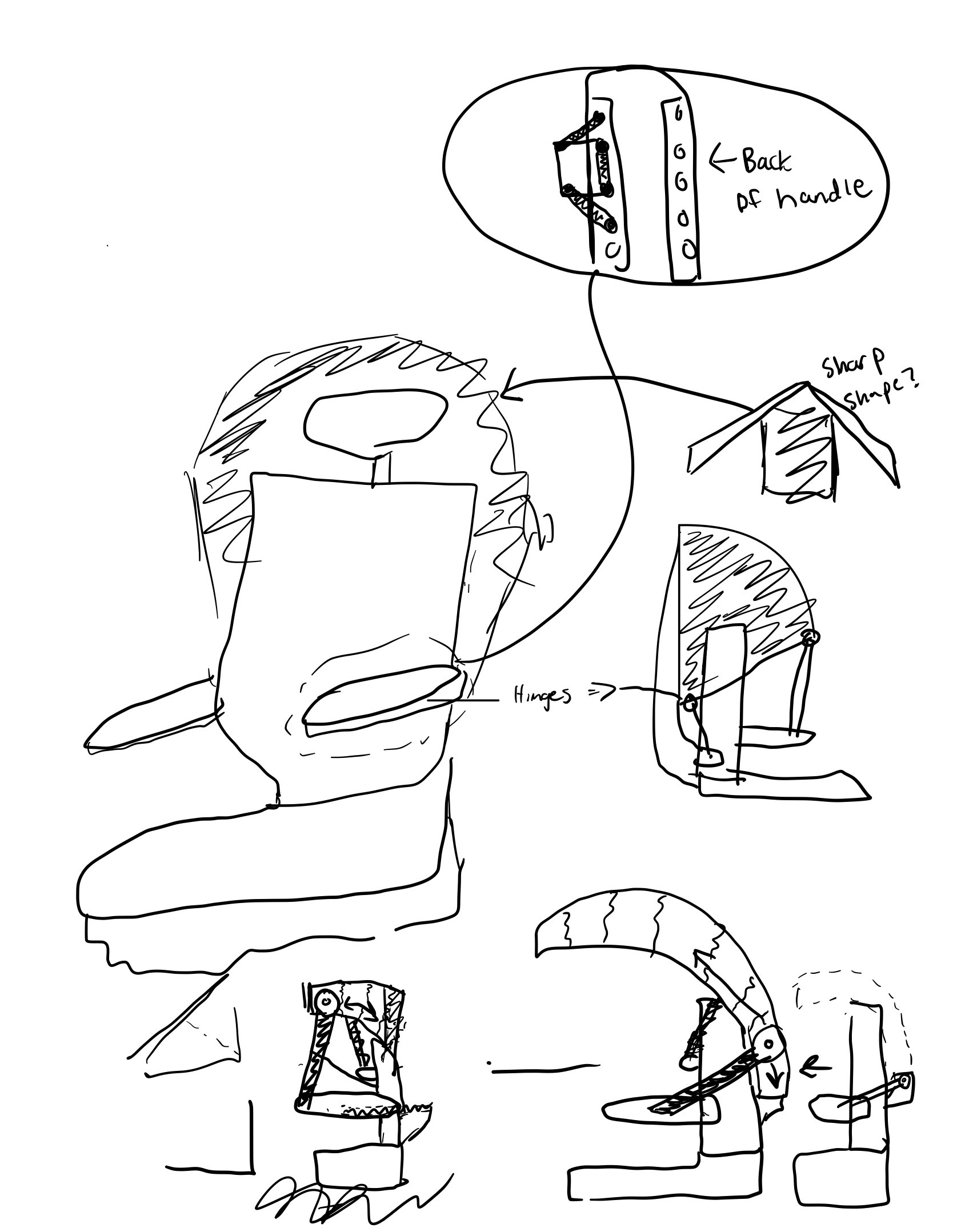

At first, we explored different shape designs to try and branch out from the classic, round, overarching "stroller" type umbrellas. Here are some of our initial sketches. Different team members also tried brainstorming about aspects like how it might fold in, how would water fall on and drain down, material, and how parts of the umbrella connected to certain parts of the chair.

MOUNTING

This part stumped us for weeks. None of us had experience with anything wheelchair-related, much less knew how to mount something on a wheelchair, and we did not have wheelchairs on hand to see or test anything physically (which would have been most ideal). Organizing a trip to PROVAIL meant schedules needed to line up with us and Julia, which was not working. Google did not provide much help either as the kind of information we needed about Permobil wheelchairs was not readily available online.

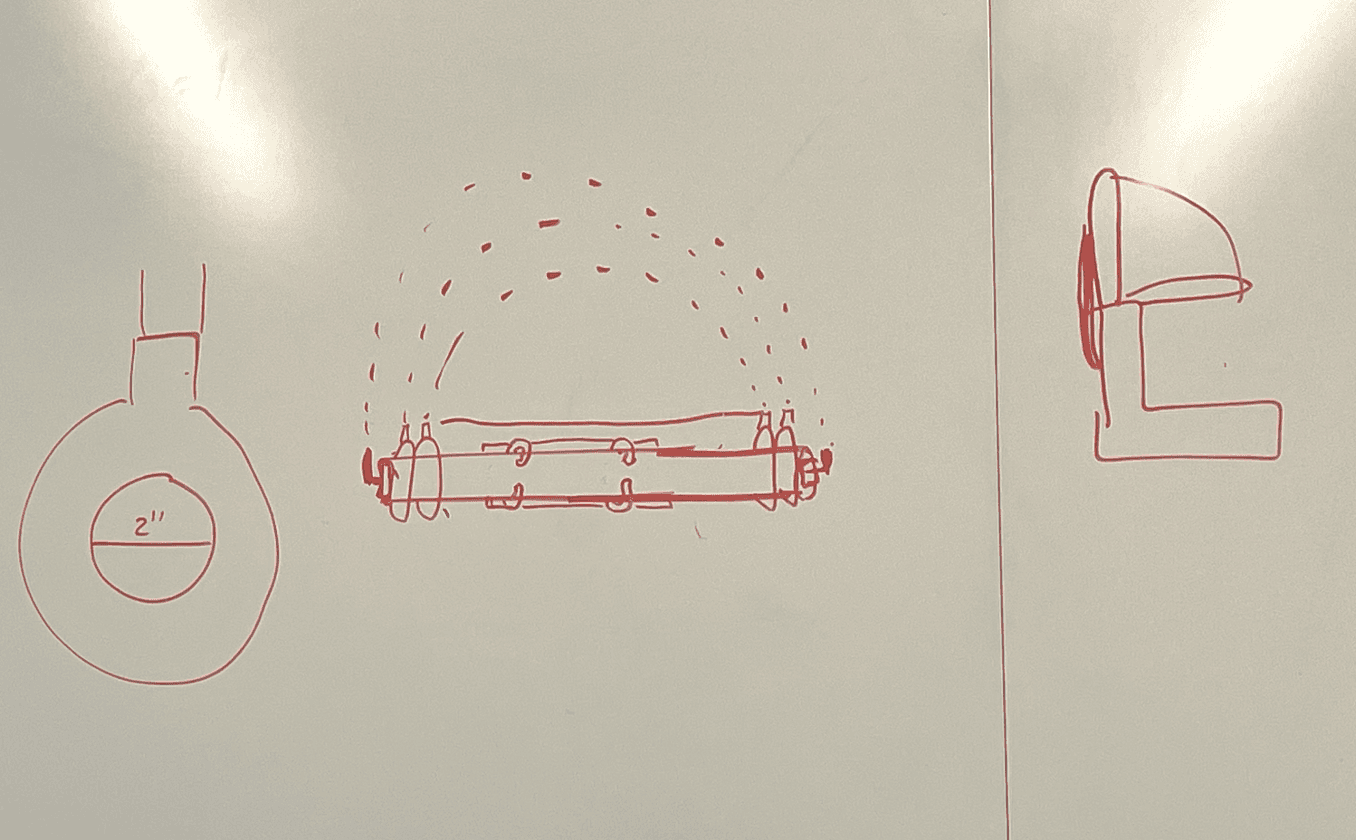

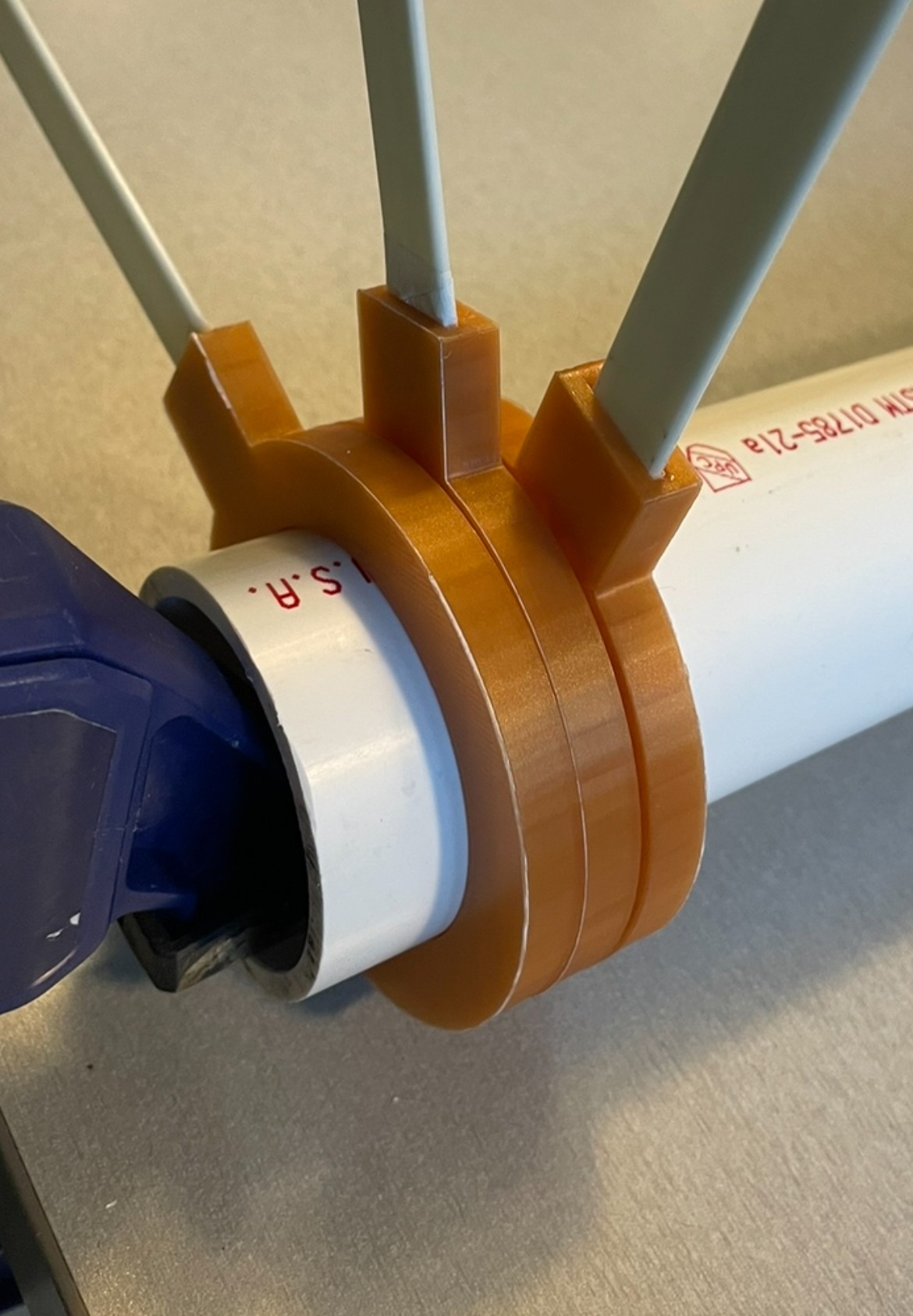

Eventually, we decided to create our own way. One pipe would go across the length of the back of the wheelchair that the umbrella poles would attach to. Finding a way for this one pipe to attach to the wheelchair was much easier than trying to attach to multiple parts of the chair (e.g. arms, side). Our idea was to 3-D print an attachment that the pipe sits in, and can be inserted into the wheelchair's tracks. And if the tracks couldn't hold it, some kind of stringy material could wrap around the pipe and hold it in place through weaving through different parts of the back of the chair like the head.

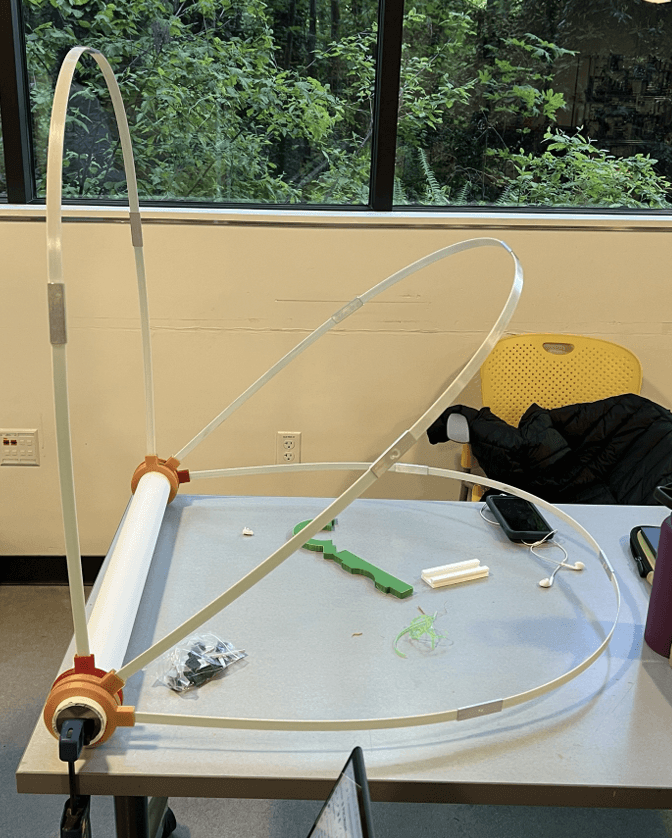

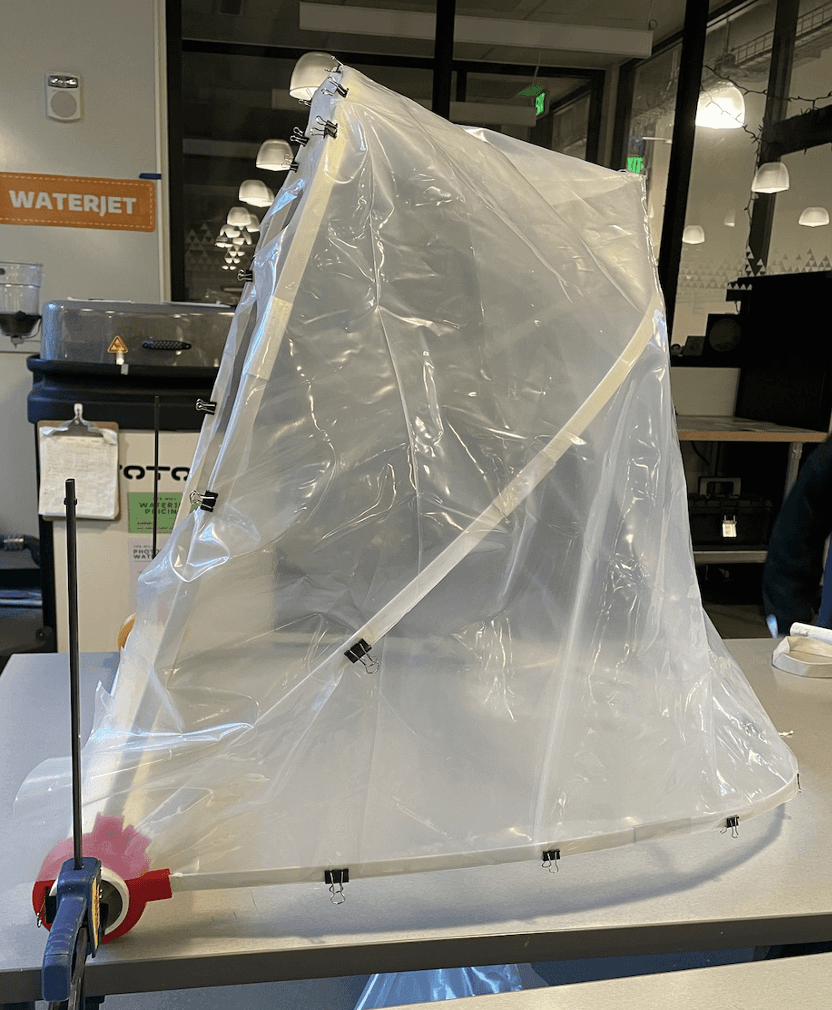

Since this idea meant that all umbrella poles had to attached to one place (the pipe), the shape of the umbrella would have to emulate that of a pullover canopy. So, we have solidified our mounting and shape ideas!

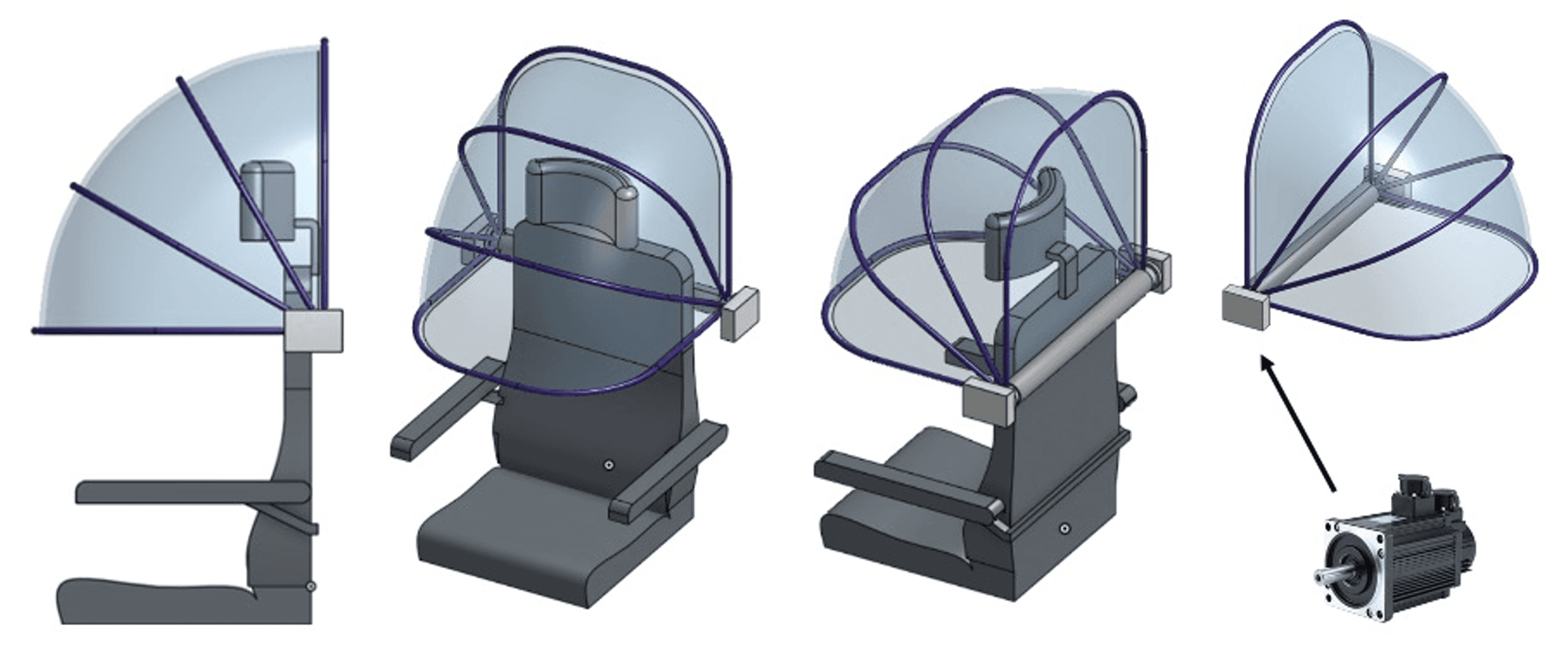

3-D MODELING

It was time to take these ideas into Solidworks and TinkerCAD (our team's preferred choices)! We also used these designs and platforms to create the attachments we needed. One was the mechanism that attached the pole to the back of the chair. The other, which took many iterations, was the attachment pieces in which went around the circle of the pipe and had a place for the umbrella poles to be inserted inside.

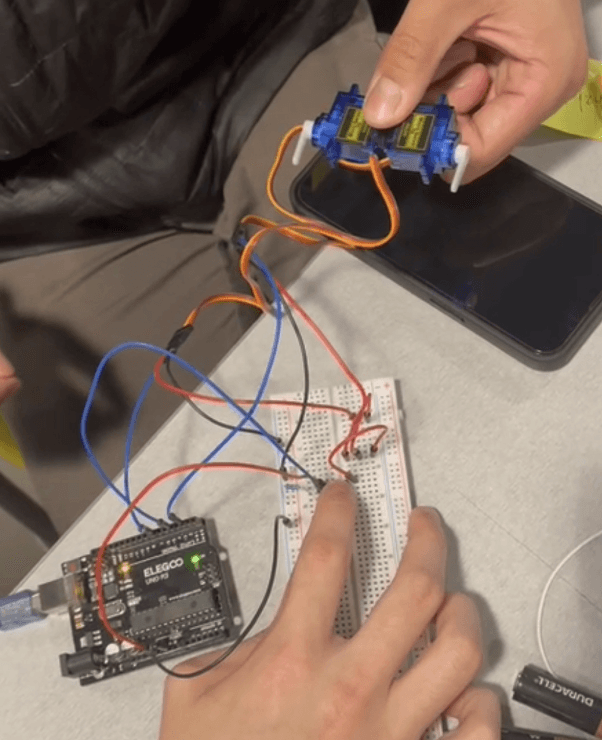

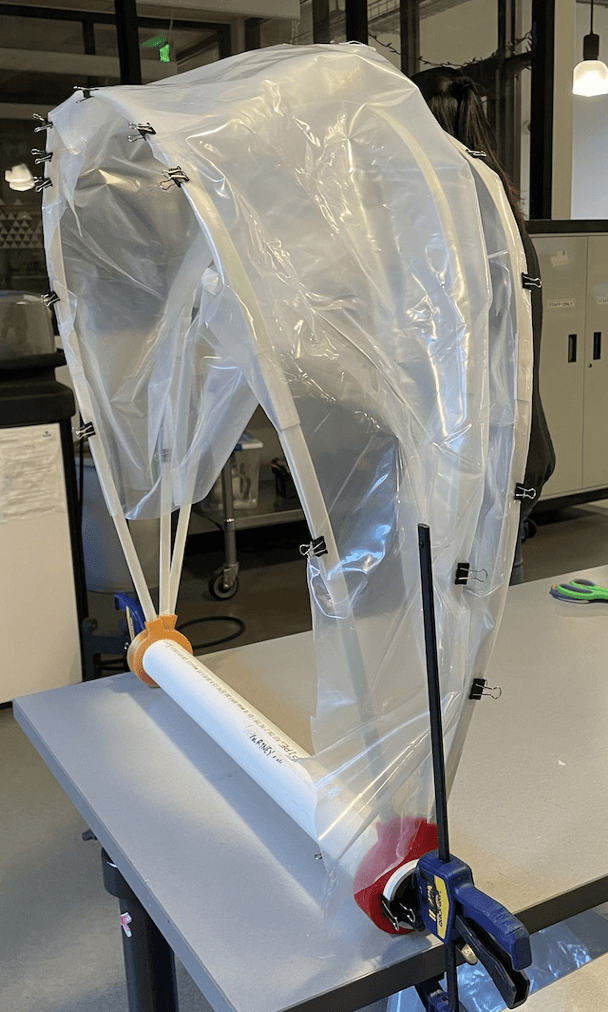

MANUFACTURING

Materials:

Umbrella poles: fiberglass poles (typically used for building canopies over greenhouses)

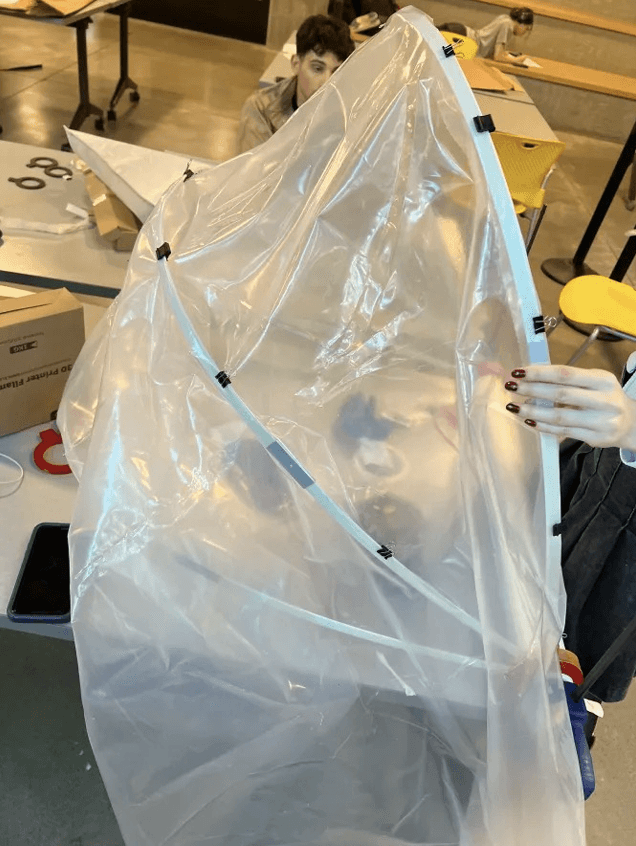

Canopy: vinyl

Pipe: PVC pipe

After we draped and cut the vinyl to fit the shape, it was glued to the poles.

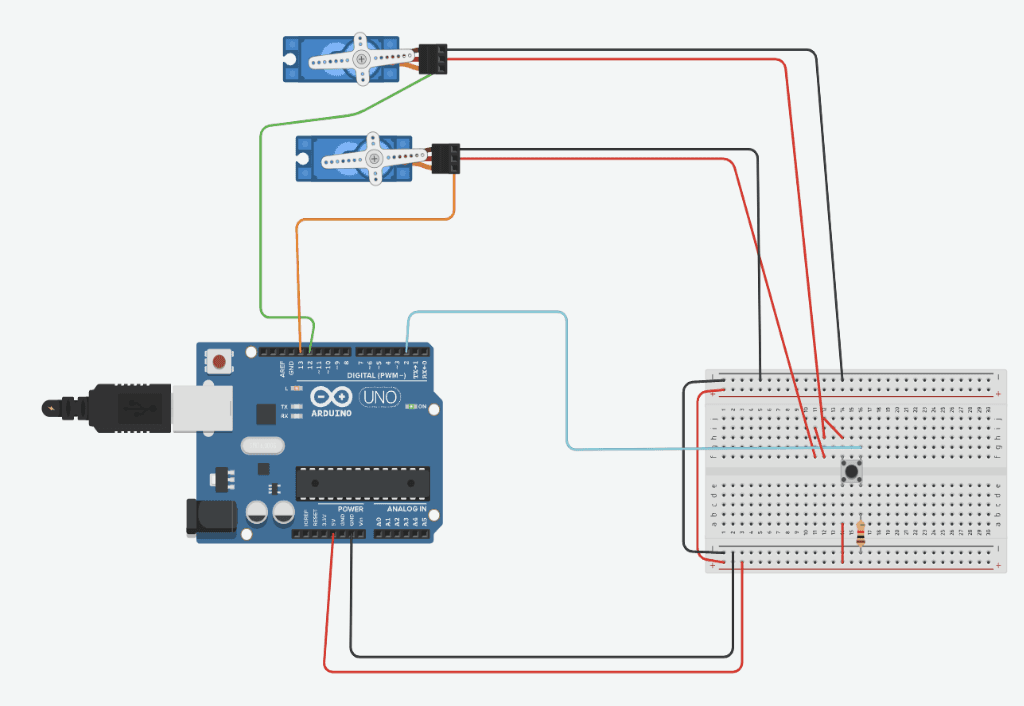

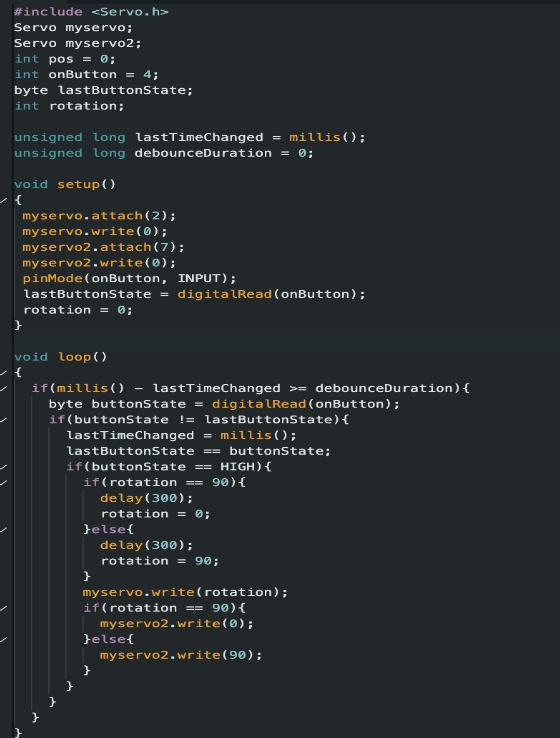

AUTOMATION FOR ROTATION

While the designers worked on the umbrella canopy, our engineers were hard at work programming an Arduino board that would power two servo motors to rotate with a press of the button. These motors would be attached to each side of the pipe and rotate each end of the outer umbrella pole to open the canopy. They also ensured safeguards were in place to handle potential issues like button spamming or other malfunction.

RESULTS

Due to time constraints and lack of supplies, we were unable to connect the servo motor legs to our umbrella poles before our final Showcase. For these same reasons, we unfortunately had no time for user testing for our final product. We were also unable to obtain a Permobil wheelchair for the Showcase because a scheduling conflict.

However, the canopy was finished and attached to the PVC pipe! We were also able to demonstrate how the press of the button rotates the servo motors legs 90 degrees to simulate the opening of the umbrella.

For our Showcase, we created a research poster to show everything we had been working on throughout the year!

Our awesome team :)